Have you tried engraving, punching, shaping the shell with a UV laser

Website: http://www.rfhtech.com

Whatsapp(Wechat): 18928466502

Email: export06@rfhlasertech.com

Using shells as accessories should be one of the oldest habits of human beings. According to research, at least 50,000 years ago, shells have been used as decorations by cavemen.

Simple and elegant shells have the characteristics of pure natural, colorfast, and no harm to the body, which is one of the reasons why we still like to use shells as decorations.

Shells are the shells of marine mollusks. The main components are calcium carbonate (CaCO3) and a part of organic matter. The composition is very simple, and when encountering light reflection, the shells can diffract into different colors, which we call "halo". After processing It can then be made into different decorations.

"

How are shells processed into decorations?

It is not easy to process the original shells into beautiful decorations. Due to the composition of the shells, the brittle and hard texture of the shells will bring a lot of difficulties to traditional processing.

New way to play! 355nm nanosecond UV laser in shell cold processing technology

Processing a shell requires a lot of processes. In addition to fermenting and cleaning the shell, it also needs to be cooked, rinsed and polished. The selected materials can enter the stage of cutting and shaping.

Among them, the biggest processing difficulty is in cutting and plasticity. As mentioned above, shells are hard and brittle. Traditional processing of shells requires a high degree of craftsmanship from the master, and it may become waste if you are not careful.

Due to the need for multiple processes in the early stage, once the scrap occurs, it is not only a matter of money cost, but also requires a lot of time and labor costs, which is not worth the loss.

"

Processing method of RFH laser

However, with the laser, it is no longer difficult to process the shells, and the shells that are like cicadas can also be engraved, punched, shaped, etc. with the RFH UV laser.

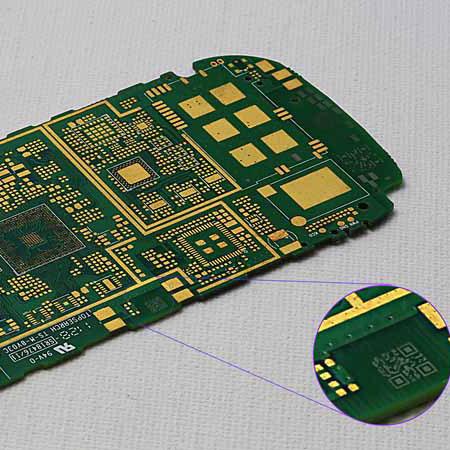

The UV laser used by RFH in the video is the latest S9 series. After the pattern is designed by the computer, the UV laser can automatically complete all operations.

Shell cutting with RFH S9 series UV laser has the following characteristics:

1 High quality cutting edge and high machining accuracy

Because RFH S9 has superior beam quality (M²<1.2), pulse width <12ns@30k, and small heat-affected area during processing, the edge is very smooth when cutting shells, with a high precision of ±0.02mm, and the processing of fine decorations is also No stress.

2 Low power consumption and low cost

RFH S9 series UV lasers use a self-developed power supply solution, which has the characteristics of low power consumption, stability and high efficiency. Due to the small size of RFH S9, it can be easily used without making a large optical path, saving enterprise costs.

3 Simple operation and easy maintenance

Unlike traditional lasers, RFH S9 supports communication with a computer and can control the laser externally through RS232, allowing the final product to have consistent quality control. In addition, due to the all-digital intelligent power control technology, it has the characteristics of simple operation and convenient monitoring, which also provides convenience in maintenance.

"

Shell processing is easy, RFH challenges the limit of materials

RFH has accumulated more than 15 years of R&D technology in the field of lasers, and has domestic and foreign professors and doctoral R&D teams with the strength to independently develop power supplies. This is the solid backing for the stable operation of RFH's entire laser system.

Due to the technical advantages of power modules, RFH can continuously challenge the limits of material processing, bring amazing achievements in different fields, and show the strength like "magic".

uv laser | green laser | Ultraviolet lasers | uv dpss laser | nanosecond laser | UV laser source | Solid State Lasers