How can 355nm UV lasers be used in industrial production?

Website: http://www.rfhtech.com

Whatsapp(Wechat): 18928466502

Email: export06@rfhlasertech.com

In modern industrial production, laser is an indispensable part. As the requirements for processing accuracy become more and more detailed, lasers are deeply involved in industrial links such as marking and cutting.

What is a laser?

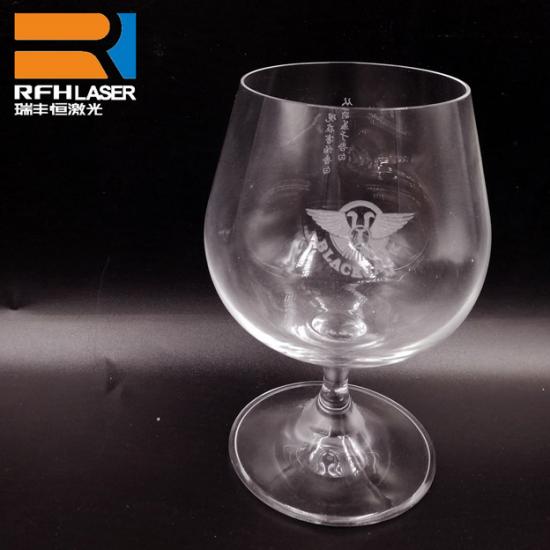

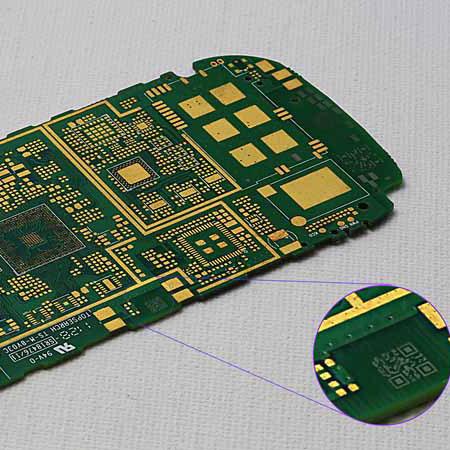

Laser cutting and marking, RFH UV nanosecond laser allows you to see different ways of playing

Quoting a comparative academic statement: a particle at a high energy level will transition from a high energy level to a low energy level when excited by a certain photon, and at the same time release a photon with the exact same frequency, phase, propagation direction and polarization state as the excitation photon. The light emitted by the excitation is called LASER, which was first translated as laser, and now we translate it as laser.

Wouldn't it be too wasteful if we just use lasers for cutting and marking, so the industry has come up with a lot of special ways to play.

Game 1: Lidar

Lidar uses the reflection characteristics of laser light to measure the precise distance between the object and the sensor by emitting laser light, which can be applied in different scenarios.

The most common usage scenario now is assisted driving or unmanned driving. Lidar is used for ranging, and the measured data is returned to the sensor to determine the next action based on this.

Since 2016, unmanned driving has officially entered the public eye from the laboratory. Today, after years of testing and optimization, more and more models have begun to carry related accessories. Although it has not yet reached the point of unmanned driving, limited assisted driving has already become a reality.

With the gradual landing of unmanned driving, the market for lidar will also increase, and the demand will show an exponential growth.

Game 2: 3D printing

In addition to the "lidar" gameplay, I believe there are many geeks who are very interested in 3D printing, which is another application scenario for lasers.

According to the data compiled by CCID Prospective Industry Research Institute, the scale of China's 3D printing market has reached 26 billion yuan in 2021, and it is predicted to increase to 32.5 billion yuan in 2022. By 2025, this number will reach 63.5 billion yuan.

In the field of 3D printing, the forming effect and precision control of laser are better. Compared with traditional metal processing technology, it has unique technical advantages.

In recent years, as a leader in the laser industry, RFH has also launched many products optimized for 3D printing. The UV laser for SLA light-curing 3D printers based on the Expert II 355 series is one of them.

At the beginning of the design, RFH adopts unique laser cavity design, special acousto-optic Q-switching technology, and high-precision cooling system, which makes the laser have the advantages of small size and high integration.

Technical advantages of RFH

After years of technical accumulation, RFH has a strong doctor-level R&D team. More importantly, RFH has the technical advantages of independent research and development of power supplies, and can improve power-related functional modules according to different application needs.

Keeping up with the times Maibo, RFH 355nm UV laser deeply participates in the development of industrial processing

In different application scenarios, RFH lasers can always innovate, keep up with the pulse of the times, and make corresponding changes in a timely manner, which is why RFH has always been a leader in the industry.

With the wide application of intelligent driving, unmanned driving and 3D printing, the demand for laser products will have a completely different order of magnitude growth, and the control of laser precision will also have higher-level requirements.

In the face of these, RFH can deal with it calmly and deeply cultivate the vertical field of laser, which is the solid backing for the stable operation of RFH's entire laser system!

uv laser | green laser | Ultraviolet lasers | uv dpss laser | nanosecond laser | UV laser source | Solid State Lasers