RFH 15W high power UV laser easily cuts 1.5mm thick silicone tape with smooth and burr-free edge

Silicone is a very common material, I believe everyone has seen it, but have you ever considered what silicone is and how it is processed.

Wondering how RFH laser cuts silicone with ease?

![]()

Silica gel in the traditional impression has two characteristics, non-toxic, tasteless and soft and skin-friendly, so silica gel is often used in some medical and health care products.

In the medical field, silicone is used in intravenous catheters, urinary catheters, blood vessels, gastroscope sleeves, etc., and of course some artificial auxiliary organs (such as artificial lungs, artificial meninges and artificial knuckles, etc.).

These silicone products are precisely processed, non-toxic and tasteless, and skin-friendly and hypoallergenic.

With the popularization of intelligent manufacturing, the processing requirements of silica gel are getting higher and higher.

Before understanding the processing of silica gel, we must first know what it is; silica gel, also known as silicic acid gel, is mainly composed of silicon dioxide, which is mainly transparent or milky white, and has micropores inside, so it has excellent adsorption.

It needs to be clear that silica gel is not artificially refined, nor is it a naturally occurring gel, but a synthetic rubber.

Silicone is different from plastic, and generally has high processing standards. Therefore, it often encounters troubles in the processing of silica gel with high temperature resistance, aging resistance, stable chemical properties, and water insolubility.

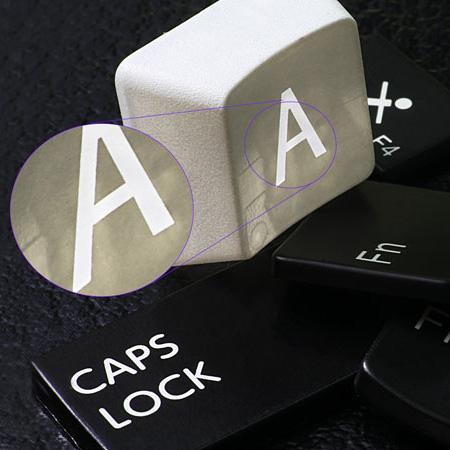

Due to the softness and smooth surface of silicone, very high production standards are required when cutting silicone, which makes the production cost skyrocket.

There is a common knowledge that the cost of silicone is actually lower than that of plastic, but because of the high production standards, the price of the final product is mostly higher.

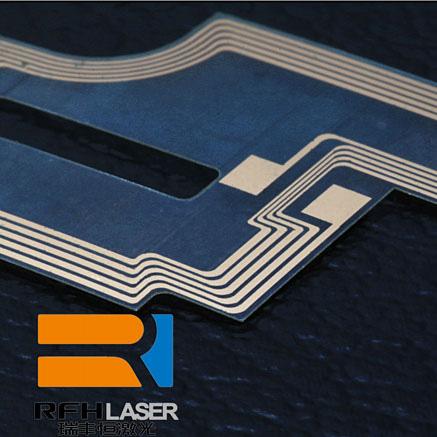

In order to reduce the cost of the enterprise, a laser is needed when cutting precision silicone; RFH uses a 15W high-power ultraviolet laser, which can easily cut 1.5mm thick silicone tape, and the cutting edge is smooth and burr-free.

Due to the precise control of the RFH UV laser, it can be easily used in precision instrument processing.

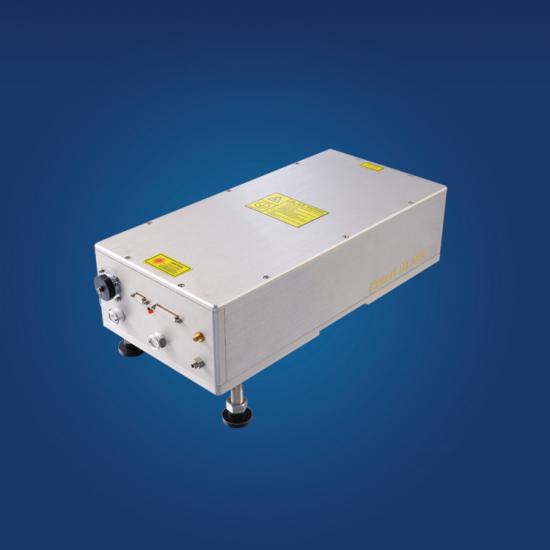

Recommended high power UV laser: Expert III 355

RFH uses this Expert III 355 in the video. As a high-power ultraviolet solid-state laser of more than 10W, the Expert III 355 is extremely small in size, but its performance is unique.

Since UV laser belongs to cold light processing, and RFH Expert III 355 has short pulse width (<25ns@50k), superior beam quality (M²<1.2) and perfect spot characteristics (spot ellipticity>90%).

The final cutting part can be smooth and controllable, and the heat-affected zone during processing is small.

In addition, in terms of power control, RFH Expert III 355 has a unique Q-switching control technology, which is suitable for various laser application control requirements; thanks to the inner cavity self-purification system, the laser has a long life and stable operation.

RFH uses a self-developed power control system, which can update the functional modules of the power control system in time, and easily adapt to the functional requirements of different scenarios.

In the context of intelligent manufacturing, RFH lasers naturally need to support all-digital intelligent power control technology, which is easy to operate and convenient to monitor; the laser can communicate with the computer through RS232, which is not only convenient for control, but also more accurate in data operation.

Under the background of Industry 4.0, RFH took the lead in completing the transformation of intelligent manufacturing, and the all-digital power control system easily meets the processing needs of the next generation.

Not only silicone, RFH laser will also easily challenge more processing methods, changing life with laser.