RFH 5w UV laser marking COVID-19 Antigen Detection Kit Batch code

The RFH 5w UV laser can quickly and accurately mark the COVID-19 Antigen Detection Kit Batch code with laser, the lines are clear and burr-free, and the marking efficiency is high. It only takes a few seconds to complete the surface marking of the COVID-19 Antigen Detection Kit Batch code black.

In mass production, lasers are widely used, among which "ultraviolet laser" is the darling of these precision processing

Ultraviolet laser is a "cold light source", so the heat effect is very small, and the effect is better when processing plastic materials, avoiding problems such as burning and deformation.

RFH S9 UV Solid State Laser

The S9 series of pulsed ultraviolet solid-state lasers in the RFH 3W-10W power range have extremely small focus spots, and the processing heat-affected zone is small, and there is almost no heat-affected damage.

In terms of precision, RFH S9 series lasers can achieve ±0.02mm high precision, and the light output is stable. At the same time, the S9 series also has a small size, which prevents users from enlarging the optical path and greatly reduces production costs.

At the moment of the epidemic, manufacturers in different fields are contributing their own efforts, and RFH Laser also hopes to use lasers to help everyone.

Plastic surface marking has very high requirements on laser power. RFH uses self-developed power control technology, which can make timely feedback and adjustments to processing to meet various needs.

In addition, the RFH S9 series belongs to the ultraviolet laser in the range of 3W~10W. If a higher power (greater than 10W) is required, a high-power ultraviolet laser is required.

Recommended RFH High Power UV Laser: Expert III 355

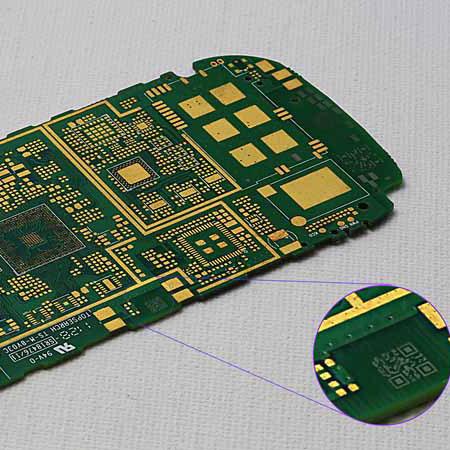

The best working power of RFH Expert III 355 is above 10W. In addition to simple plastic surface marking, it is also widely used for PE/PCB/FPC cutting, glass, sapphire cutting, and high-precision micromachining for drilling, scribing, cutting, etc. field.

The laser wavelength of RFH Expert III 355 is 354.7nm, the repetition rate covers a wide range (single pulse to 200kHz), and the beam quality is strictly guaranteed in all frequency ranges (M2<1.2).

In terms of power supply technology, the RFH autonomous control system is still used, and it has a unique Q-switching control technology, which is suitable for various laser application control requirements.

Considering the simplicity and convenience of post-operation and maintenance, RFH Expert III 355 chooses all-digital intelligent power control technology, which is easy to operate and convenient to monitor; it supports connecting to a computer through the RS232 serial port, and can control the laser externally.

Laser Application Demonstration:

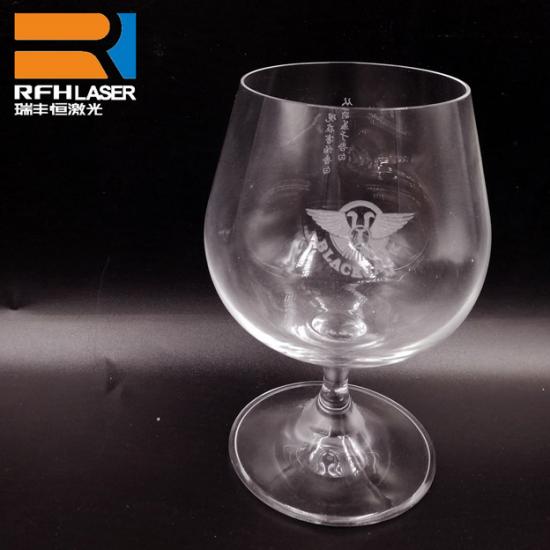

In addition to the plastic surface marking in the video, the RFH UV solid-state laser can also mark multiple surfaces such as ceramics, glass, PCB, metal, and carbon fiber

At the same time, it can also cut glass, ceramics, PCB and other materials, which are widely used in various fields.

After 15 years of ingenious forging, RFH Laser is now a global manufacturer of industrial-grade all-solid-state lasers. It can't help but have continuous innovation capabilities in products and shoulder social responsibilities.

At the moment of the epidemic, I hope that everyone in front of the screen will take care of their health, do not go out unless necessary, and take good protection when going out, so that everyone can overcome difficulties and survive the epidemic safely.