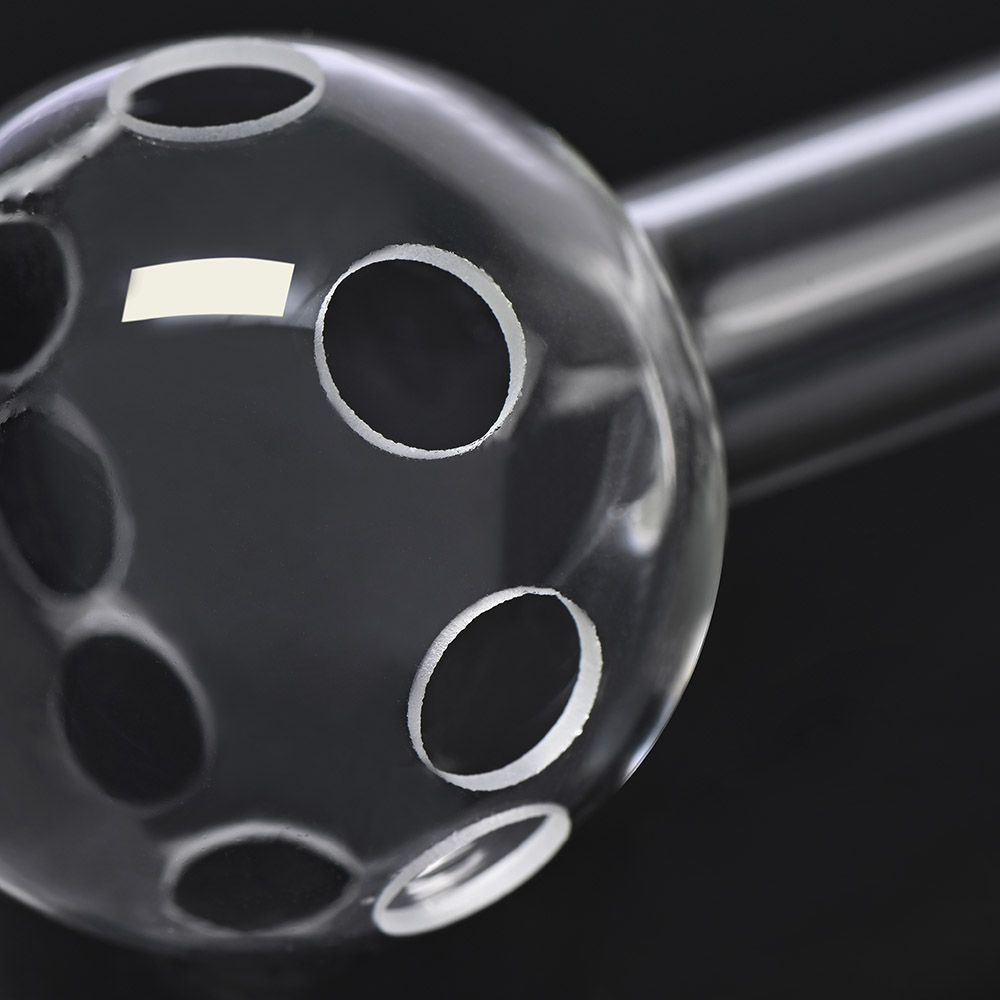

RFH 20W UV laser cutting glass edge is smooth and without burrs, high accuracy

The glass processing we use in daily life is nothing more than marking and cutting, and cutting holes is the most troublesome action of all cutting.

If you tell you, the RFH laser can be marked+cut holes at the same time, what do you think?

Due to the existence of ultraviolet lasers, marking+cutting holes in one go, which not only improves efficiency, but also the ultimate effect is impeccable.

RFH uses ultraviolet laser known as "cold light", which has a small heat impact, so cutting edges is smooth and without burrs, and the accuracy is extremely high.

Traditional glass punching?

In addition to laser widely used in glass processing, traditional processing methods are still used in many places.

From the perspective of glass cut holes, the traditional glass cut hole needs to use a dedicated glass drill. After the glass is marked on the glass, start to punch. The entire operation requires a strong technical force.

When cutting the glass with the drill bit, you need to remember two points. One is slow and slow, and the other is to keep adding water to cool down, otherwise the drill bit is prone to damage.

Even so, the glass -cut holes processed by traditional methods are still unsatisfactory; the edges of the holes can be clearly seen that the burrs and all the traces of heating color degeneration can be seen, and the cutting accuracy is simply grasped by the processing master, and the quality control is difficult to quantify.

Advantages of laser processing:

It is the shortcomings of traditional processing methods. Laser -free processing methods have become the first choice for modern glass processing. Among them, many traditional processing advantages cannot be replaced.

1. Computer control, high degree of automation.

2. The heat effect can be controlled, and the good product rate can be quantified.

3. The cost of processing consumables is low and the return on investment is high.

4. It is easier to achieve precision processing.

5. Make irregular graphics cut possible.

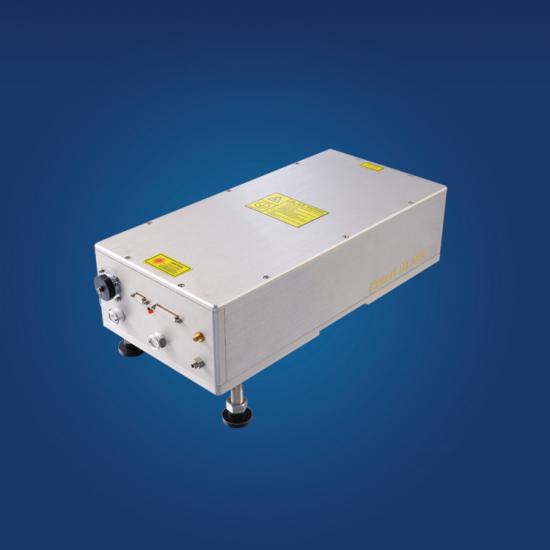

RFH Recommendation: Expert III 355 High -power UV -Pulse Solid Laser

If you want to cut the glass quickly and precisely, 10W+high -power ultraviolet solid laser is obviously the first choice.

RFH Expert III 355 series UV -semiconductor pump pumping solid laser, adopts unique laser cavity design, sound light q technology, and high -precision cooling system, small volume and high integration.

In industrial processing, due to the superior beam quality (M2 <1.2), it is strictly guaranteed within all frequency range and has high precision ± 0.02mm.

In addition, the RFH Expert III 355 uses unique Q qi control technology, which is suitable for various laser application control requirements; the inner cavity self -purification system makes the laser long life and stable operation.

Under the power control system independently developed by RFH, the RFH Expert III 355 can update and improve the functional module in time to give full play to the technical advantages and suitable for various usage scenarios.

As for the control method, the RFH Expert III 355 uses full digital intelligent power control technology to operate simple and easy to monitor; supports communication with computer, and can control the laser through RS232 external control.

Under the continuous catalysis of Industry 4.0, the requirements for automation, digitalization, and personalized processing are becoming more and more important. RFH laser as a global industrial -grade all -solid laser manufacturer has not stopped innovation.

Under the traditional advantages of "high stability" and "high cost performance", the accumulation of power technology independently develops power supply technology, as well as strong technical teams, is a solid backing for the stable operation of the RFH laser system.

Just as the "real gold is not afraid of fire, good things can stand the test" shown in the video, the RFH laser is not afraid of challenges.