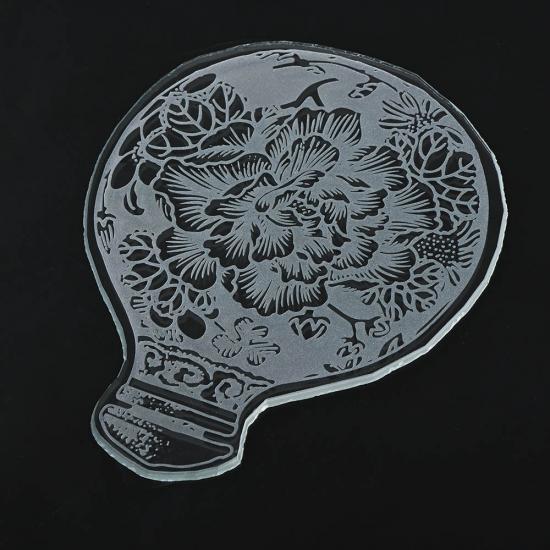

RFH 15W high power UV laser marking tempered glass without bursting

It is not uncommon to mark on glass. It is precisely because of the huge demand for glass products. On the contrary, glass marking has a wide range of applications, and lasers play an important role in it.

Have you ever considered how the button guides and LOGO are engraved on the tempered glass of those electrical appliances?

That's right, it is through laser "marking".

The act of "marking" is to leave an indelible mark on the surface of the material, which can be a pattern, text or QR code, etc. In modern industrial products, laser is the main way of marking. Different types of lasers are used according to different materials and marking requirements.

Do you know what type of laser is needed for tempered glass marking?

RFH uses a 15W high-power ultraviolet laser, which can easily achieve fine marking, and LOGO, barcode, QR code, production batch number and other information can be perfectly supported.

Due to the accurate power control of the RFH high-power ultraviolet laser, the final marking effect is fine, beautiful and generous, and it is not timid in the face of high-strength tempered glass.

Originally, marking on glass was a very difficult task, but once the power control is not in place, the thermal influence will destroy the accuracy of lines or text, and the final effect will be ugly, and even the whole piece of material will be destroyed in severe cases.

RFH uses the ultraviolet laser known as "cold light", under the high power of 15 watts, not only minimizes the thermal impact, but also has extremely high processing efficiency. In the era when a large number of electrical appliances need to use tempered glass, this efficient processing method is exactly what everyone is pursuing, and it is also a sharp tool to improve the processing accuracy of industrial products.

How to choose the right laser equipment?

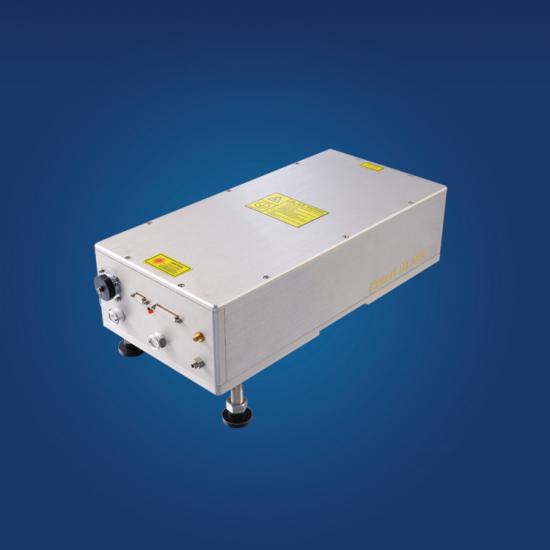

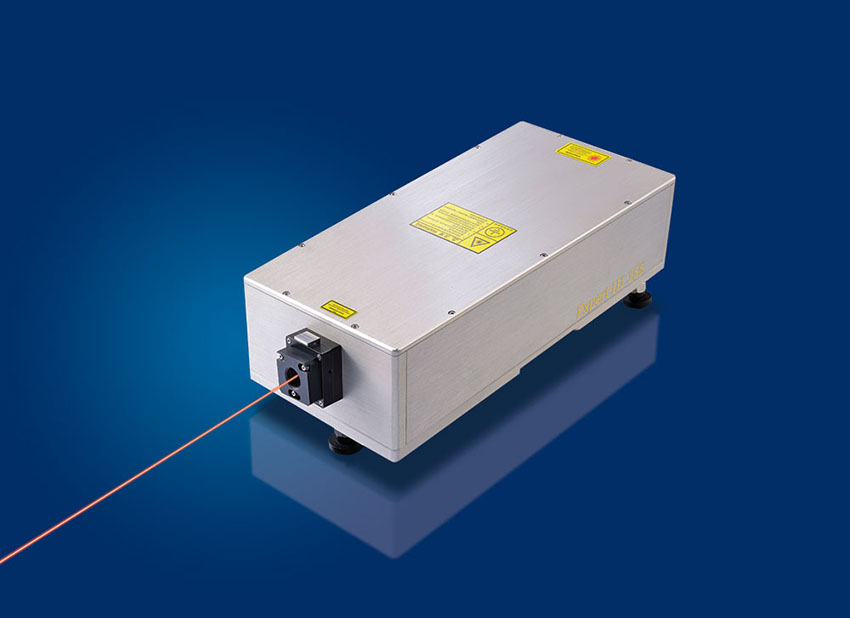

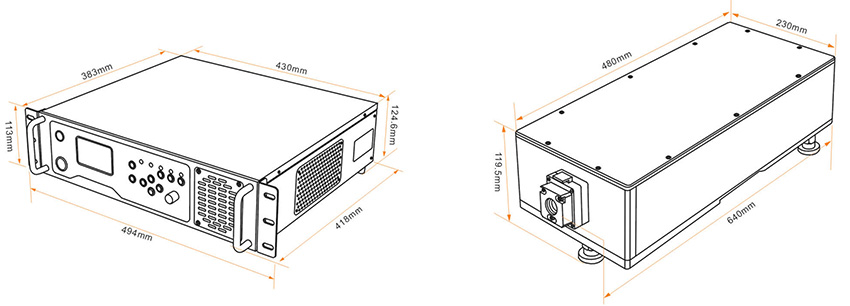

For high-power ultraviolet laser requirements, RFH recommends Expert III 355 high-power ultraviolet pulsed solid-state laser; this laser can easily meet the ultraviolet laser processing requirements above 10W, and has the advantages of fast processing speed, high precision, strong stability and small size. With the industry's top industrial standards.

High precision processing level

RFH Expert III 355 has a laser wavelength of 354.7nm, a wide repetition rate coverage (single pulse to 200kHz), and the beam quality is strictly guaranteed in all frequency ranges.

In terms of function, thanks to the pulse width <25ns@50k, the heat-affected zone is very small during processing, the processing is slim, and the lines can be clearly seen, which can achieve ±0.02mm high precision

Power module with super stability

The power supply is the heart of a laser, and even directly affects the performance of the laser. RFH has its own power supply technology. RFH Expert III 355 uses unique laser cavity design, acousto-optic Q-switching technology, and high-precision cooling system, with small size and high integration.

Due to the addition of the inner cavity self-purification system, the laser has a long life and stable operation.

Simple operation, convenient operation and maintenance

Not only is the quality of the hardware itself extremely high, but in terms of control, RFH Expert III 355 adopts all-digital intelligent power control technology, which is easy to operate.

During daily operation and maintenance, RFH Expert III 355 supports communication with the computer, and can externally control the laser through RS232; thanks to the integrated design, it is easy to integrate with various devices and has a wide range of application scenarios.

As a global manufacturer of industrial-grade all-solid-state lasers, RFH has a number of core technical advantages, and through continuous innovation and research and development, it can easily challenge the processing of different materials. Adhere to the concept of "technology changes life" in practice, focus on laser for 15 years, will continue to cultivate in this industry, and strive to create the next 15 years of glory.