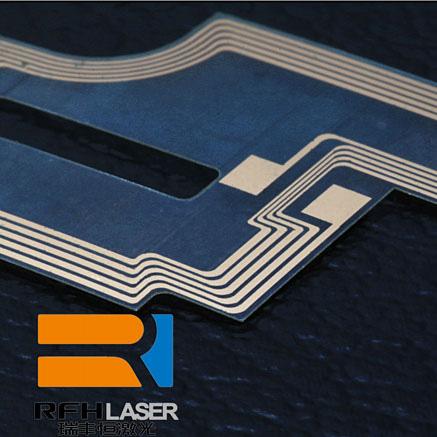

RFH 3W5W UV laser 355nm cutting PET film without deformation

Website: http://www.rfhtech.com

Whatsapp(Wechat): 18928466502

Email: export06@rfhlasertech.com

When it comes to laser applications, RFH has the determination to continue to challenge, even a small PET film can be easily won!

RFH UV laser has unique technology to cut plastic film so efficiently

Don't underestimate plastic film, it is very important in daily life. According to different forms such as colored, transparent, reflective, etc., PET film is widely used in various fields.

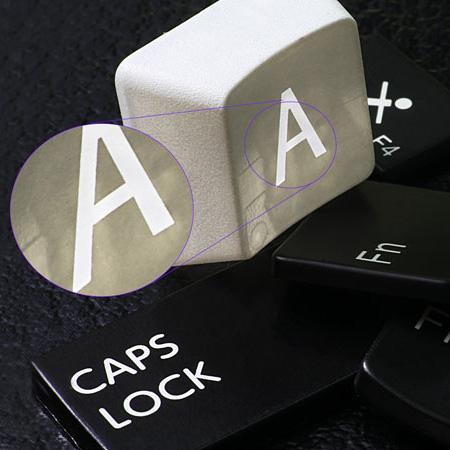

Friends who know a little about material punching and marking should know that PET film is more sensitive to temperature. If the heat affected area is too large, it will inevitably cause deformation problems.

If you want to process well, laser is of course the most perfect solution. At the same time, processing requires extremely high beam quality of laser. The energy must be controlled at a tiny point, so as to reduce the heat affected area.

Nanosecond UV laser on-the-fly punches and cuts PET film, no problem at all

When the quality of the laser beam is not good, it is easy to destroy the material, increase the scrap rate and increase the production cost, which is not worth the loss.

As mentioned at the beginning of the article, RFH lasers are unique and challenge PET films of various materials. No matter which type they are, they can be easily marked, cut, and punched, without burrs or deformations on the edges.

To achieve such efficient cutting applications, RFH UV lasers have their own unique methods.

01 Independent research and development of power supply

The first to bear the brunt of course is the power supply independently developed by RFH. The beam quality, stability and maximum performance of the laser are all closely related to the power supply.

The power supply of the UV laser is like a heart. A strong heart can be adjusted freely. RFH has the technical strength to independently develop the power supply, which is also a major guarantee of stability.

02Full digital intelligent power control system

Entering the digital age, digitalization is the general trend, whether adjusting laser parameters or monitoring operating status. RFH Laser is the first to complete all-digital intelligent power control technology.

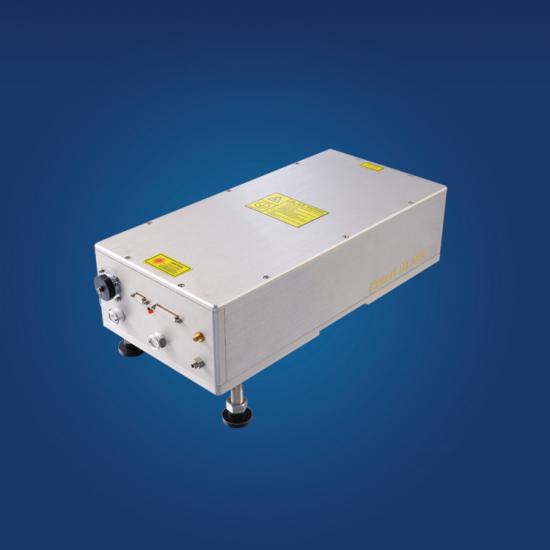

Recommended Laser Products: RFH S9 UV Laser

RFH S9 UV laser is the latest product of RFH, which integrates the most advanced technology of RFH, which can provide users with the best experience.

01 Small size and strong scalability

The RFH S9 UV laser has the advantage of small size and can be easily installed on various flying marking equipment, saving space and reducing costs, killing two birds with one stone.

02Quality Assurance

On the core components, RFH S9 UV lasers are all imported brands, and all components are cooperating with domestic first-line brand suppliers, and the quality of components is guaranteed.

03Superior beam quality

In terms of beam quality, the RFH S9 UV laser has a strict guarantee, the superior beam quality (M²<1.2) is the guarantee of the finished product, the pulse width is <12ns@30k, and the heat affected area is very small during processing.

04 Strong system experience integrity

In order to maximize the performance of the laser, RFH provides a complete system sales solution, including power supply, laser head and cooling system, in order to provide users with the most stable experience.

RFH focus on laser confidence unchanged

After 15 years of technology accumulation and research and development, RFH has a research and development team of professors and doctorates at home and abroad, and the confidence to focus on lasers remains unchanged.

From procurement to final delivery inspection, RFH is checked at every level, and all production environments use dust-free workshops without pollution, which is why the life of RFH lasers is better than that of similar products.

uv laser | green laser | Ultraviolet lasers | uv dpss laser | nanosecond laser | UV laser source | Solid State Lasers