RFH 532nm green laser high-end marking car windshield LOGO

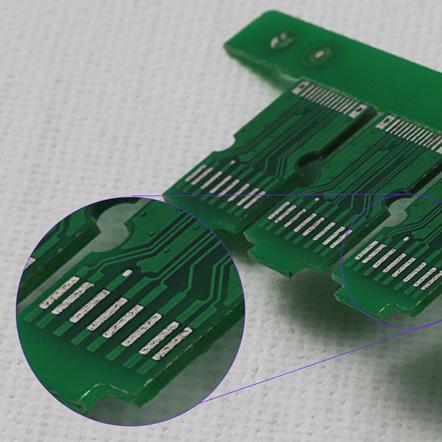

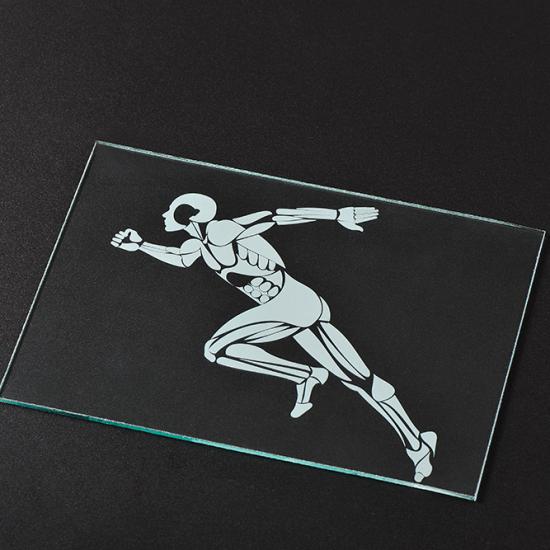

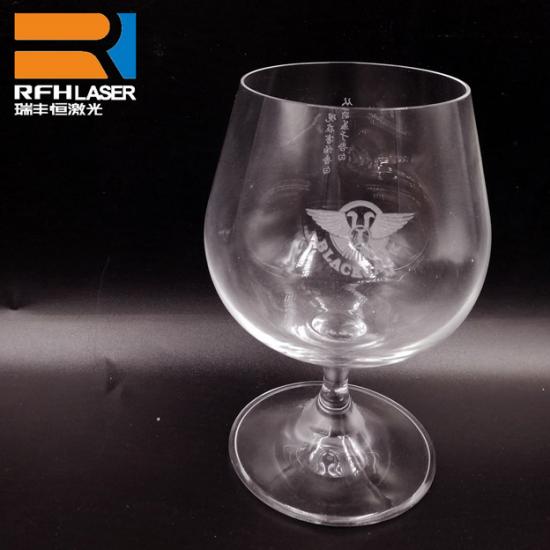

The customer uses the RFH green laser to hit the car windshield with high-definition, no blur

As an important part of car appearance, car windshield has strict requirements in production. The green laser marking logo on the windshield has also caused a lot of trouble in the industry. Some glass manufacturers once thought that the logo on the windshield should not be too tangled, so they used a weak marking technique. But it makes the quality unable to pass. Therefore, it can be seen that the text and pattern content such as the logo and model number marked on the windshield not only need to be fully presented on the glass, but also need not be corroded during the long-term baptism of wind and sand.

The windshield marked with RFH 532nm green laser can ensure the completeness and correctness of the picture to a large extent, and it can also ensure that it will not become blurred during long-term driving, so that it can be used for a long time. Longer.

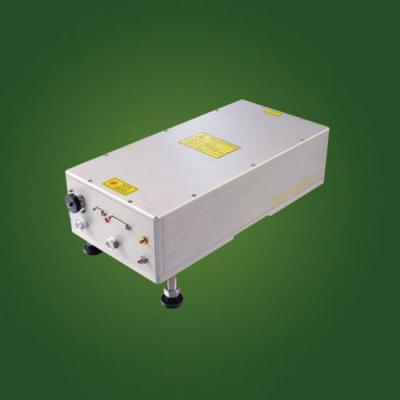

"±0.002mm high precision", "high stability" and "high cost performance" are the core advantages of RFH green lasers

The wavelength of the green laser is 532nm, and its small wavelength determines that it has high beam quality, small spot size, and can achieve the ultra-fine marking requirements of car windshields. Its minimum character can reach 0.02mm.

532 green laser has a wide range of repetition frequency, single pulse to 200kHz; in all frequency ranges, it is strictly guaranteed to have superior beam quality (M²<1.3) and perfect spot characteristics (spot ellipticity>90%), which is very suitable for ultra-fine Marking; In addition, the pulse width of the green laser is less than 35ns@30k, and the heat-affected area is small during processing, and there will be no scorching or deformation. The unique Q-switching control technology is suitable for various laser application control requirements; It adopts all-digital intelligent power control technology, which is easy to operate and convenient for remote monitoring.

The professor-level team at home and abroad independently develops the laser dedicated power control system to reduce the failure rate

There is a one-to-one correspondence between the power supply and the laser. The stability of the power supply control system determines whether the laser can maximize its performance during operation. RFH has the advantages of independent research and development of power supply technology, which can update the function modules of the power control system in time and improve the function modules according to the needs of the laser. 12 years of R & D technology accumulation, domestic and foreign experts, doctoral level R & D team.

This is a solid backing for the stable operation of RFH's entire laser system.

The core components of green laser products adopt imported brands, which are super cost-effective

The core components of the pump and Q switch are imported brands, and the parts cooperate with domestic first-line brand suppliers. From the source of the material procurement ecological chain, ensure the quality of each component.

This is a guarantee of confidence for users to use RFH brand lasers.

Power supply + laser head + cooling system, complete system sales

From the perspective of users, RFH has launched a complete laser system sales plan to ensure the stability of the complete laser system and give full play to its best performance.

uv laser | green laser | Ultraviolet lasers | uv dpss laser | nanosecond laser | UV laser source | Solid State Lasers