RFH high-power ultraviolet laser cutting wafer with fast speed, high accuracy, and no burrs

With the rapid development of artificial intelligence technology, the demand for intelligent devices, intelligent networks, intelligent manufacturing and other fields is growing day by day, and the core of these fields cannot be separated from an important component: wafers.

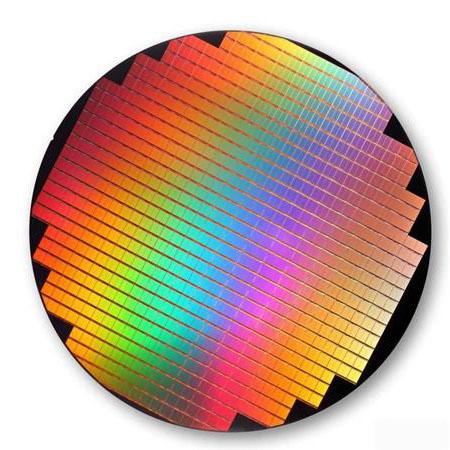

A wafer is a thin and flat silicon wafer with many tiny circuits engraved on it, which can be used to manufacture products such as integrated circuits and chips. The quality and performance of wafers directly affect the final product performance and application range.

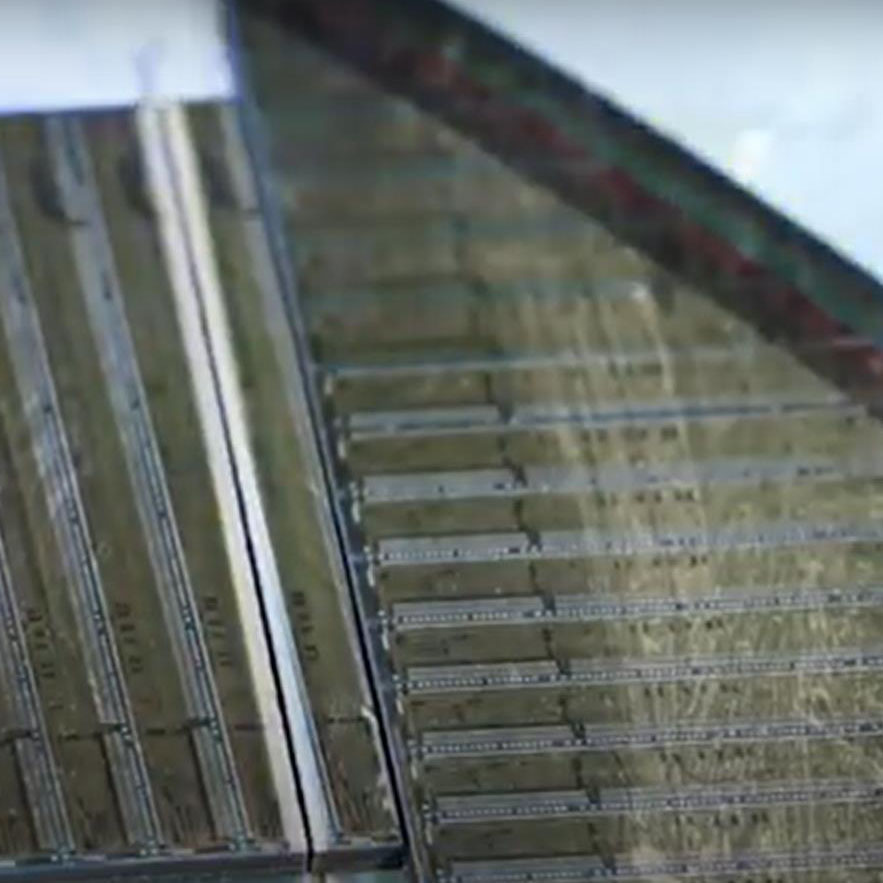

However, wafer processing is not easy as it requires multiple steps, with the most critical step being cutting.

Wafer cutting is the process of cutting large silicon ingots into individual wafers. This process has high requirements for the quality, size, flatness, surface roughness, and other aspects of the wafer, while minimizing material loss and waste.

The traditional cutting method is mainly mechanical cutting, but this method has some drawbacks, such as slow cutting speed, low cutting accuracy, burrs on the cutting surface, and high cutting temperature, which can affect the quality and performance of the wafer.

In order to solve these problems, a new cutting method has emerged: ultraviolet laser cutting.

UV laser cutting is to use UV laser beam to conduct non Thermochemistry reaction on silicon ingot, so that it can be directly gasified or evaporated, thus achieving efficient, accurate and burr free cutting. UV laser cutting has the following advantages:

-Fast cutting speed.

UV laser cutting can achieve a cutting speed of hundreds of meters per minute, which is much faster than traditional cutting methods.

-High cutting accuracy.

UV laser cutting can achieve sub micron level cutting accuracy, which is much higher than traditional cutting methods.

-The cutting surface is free of burrs.

UV laser cutting can directly vaporize or evaporate silicon ingots without generating any residue or debris, making the cutting surface very smooth and clean without the need for subsequent polishing or cleaning.

-The cutting temperature is low.

UV laser cutting is a type of cold light cutting that does not have a thermal impact on the silicon ingot and therefore does not cause deformation or damage to the wafer.

The precise cutting of crystal wafers by RFH laser relies on powerful technical capabilities, specifically the precise control of laser power.

As a global industrial grade all solid-state laser manufacturer, "± 0.02mm high precision", "high stability", and "high cost-effectiveness" are the core advantages of RFH ultraviolet lasers. After 16 years of craftsmanship and forging, RFH has a doctoral level research and development team that independently develops a laser specific power control system. It is able to update the power control system functional modules in a timely manner and improve them according to laser needs.

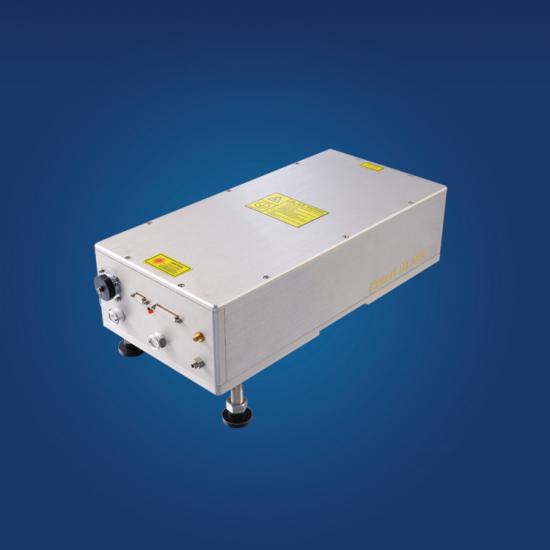

Recommendation for RFH high-power ultraviolet laser: Expert III 355

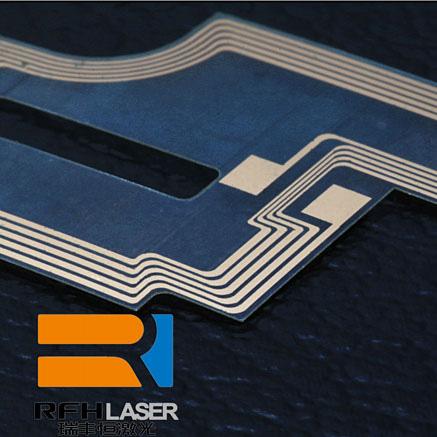

RFH Expert III 355 is widely used in fields such as PE/PCB/FPC cutting, glass, sapphire cutting, and high-precision fine machining for drilling, marking, and cutting.

In terms of design, RFH Expert III 355 adopts a unique laser cavity design, acoustooptic Q-switching technology, and high-precision cooling system, with small volume, high integration, and superior beam quality (M ²< 1.2) and perfect spot characteristics (spot ellipticity>90%).

As a 10W-15W high-power ultraviolet laser, RFH Expert III 355 adopts an all digital intelligent power control system, which is easy to operate and convenient for monitoring. When performing precision operations such as wafer cutting, it is possible to communicate with a computer and control the laser externally through RS232, resulting in precise cutting, smooth edges, and no burrs.

UV laser cutting is an efficient processing method suitable for the AI era, which can improve the quality and performance of wafers, reduce the cost and resource consumption of wafers, and provide strong support for the development of artificial intelligence technology.