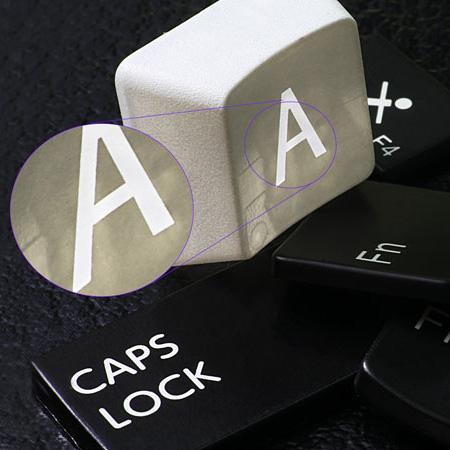

Ultraviolet laser has low thermal influence and high precision

In the laser marking processing industry, laser equipment is the most important production tool, and the stability of laser equipment affects the efficiency of the entire factory. The laser is the core part of laser equipment. Therefore, laser equipment manufacturers pay special attention to the quality of their products when purchasing lasers.

So, what about the quality of the laser? Today, RFH Laser Editor recommends a method to everyone: from the manufacturer's production process, especially the inspection process.

A high-quality laser must be able to withstand multiple tests, otherwise it will fail during long-term continuous operation when used in actual production and processing.

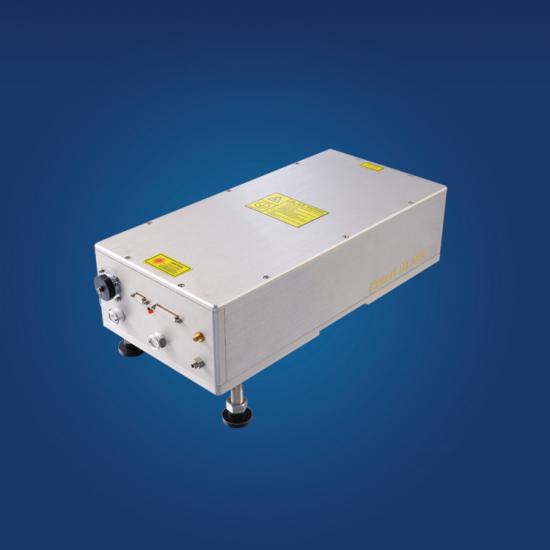

Next, let's take a look at the high-quality 355nm UV lasers of RFH that go through several inspections before shipment.

Pre-production quality inspection and control: each component is tested to ensure that the components are 100% qualified before it can enter the production material reserve; early-stage wiring-testing and sealing-debugging, layered checks, quality assurance; finished product testing: all products pass Strict aging test, product parameters such as power, beam quality, spot ellipticity, beam pointing stability, etc. must be 100% up to the standard; warehousing quality inspection: strictly in accordance with the "product warehousing inspection standards", the machine parameters and accessories conform to 100% Only allow storage; pre-delivery inspection: turn on again to test the equipment power, spot ellipticity, beam direction, and other parameters, and the accuracy rate is 100% before delivery.

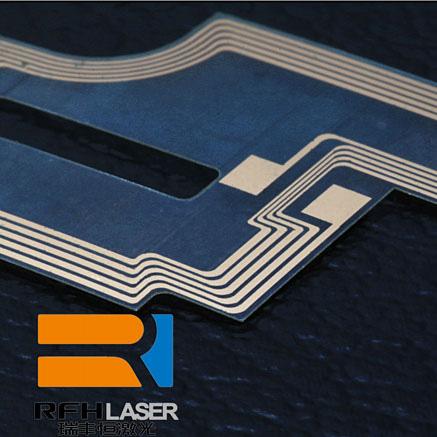

It is this multiple detection that allows the RFH 355nm UV laser to maintain constant beam quality and high-efficiency power consumption under extreme industrial and scientific research conditions, and conquer many domestic and foreign laser equipment manufacturers with its superior quality of fast speed and fine effects , Is used to manufacture a variety of high-precision laser marking equipment such as food packaging laser marking machine and pharmaceutical packaging laser marking machine.

Of course, it also depends on what technology the laser has.

RFH 355nm UV laser has self-developed all-digital intelligent power control technology, which can update the power control system function modules in time, and improve the function modules according to laser needs to ensure the stable operation of the entire laser system; it has unique Q-switching control technology, suitable for all This kind of laser application control needs; has an internal cavity self-purification system, which makes the laser long life and stable operation.

This first-class quality UV laser is the result of 12 years of RFH cultivation.