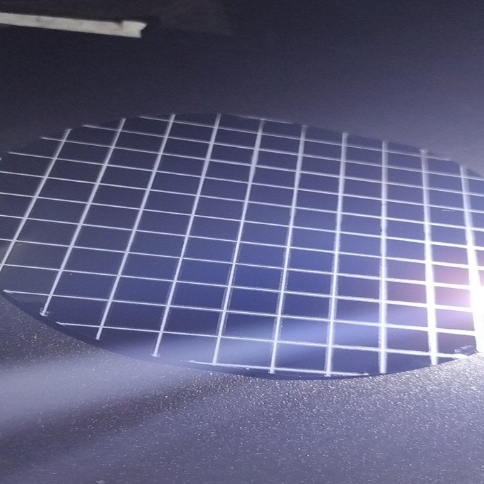

Water Cooled UV Laser Source drilling silicon wafers

Powerful Precision: Water-Cooled UV Laser Source Revolutionizes Silicon Wafer Drilling

In the realm of semiconductor manufacturing, intricacies abound, with the drilling of silicon wafers taking center stage. As technology advances, the demand for more precise and efficient drilling methods escalates, leading to the emergence of a transformative solution: the water-cooled UV laser source. This cutting-edge technology has revolutionized the industry, offering unparalleled power, accuracy, and reliability, elevating the art of silicon wafer drilling to new heights.

Traditionally, silicon wafer drilling has been a complex and time-consuming process, often plagued by challenges such as thermal damage, debris accumulation, and irregular hole shapes. However, with the introduction of the water-cooled UV laser source, these obstacles have been overcome, facilitating a groundbreaking approach to drilling that guarantees exceptional results, every time.

At the heart of this revolutionary technology lies the water-cooled UV laser source's extraordinary power. Utilizing high-energy ultraviolet light, this laser source delivers a concentrated and controlled beam that allows for precise material removal without compromising the integrity of the silicon wafer. By harnessing the strength of this advanced light source, manufacturers can achieve clean and uniform holes, even in the most intricate patterns, ensuring optimal functionality and performance of the finished product.

The precision afforded by the water-cooled UV laser source is incomparable. Its tightly focused beam enables micron-level drilling accuracy, leaving little room for error. This heightened precision allows manufacturers to create micro-sized holes with utmost control and consistency, crucial for the advancement of microelectronics and other cutting-edge technologies. By employing such exacting techniques, the water-cooled UV laser source empowers manufacturers to push the boundaries of innovation, meeting the ever-increasing demands of the digital era.

Furthermore, the water-cooled feature of this laser source enhances its performance and reliability. By circulating coolant through the system, excessive heat generated during the drilling process is efficiently dissipated. This crucial cooling mechanism mitigates the risk of thermal damage to the silicon wafer, ensuring its structural integrity remains intact. The elimination of thermal stress and associated deformations guarantees a superior-quality product, bolstering the confidence of manufacturers in their ability to deliver excellence in a competitive market.

In addition to its power and precision, the water-cooled UV laser source offers unparalleled versatility. Its adaptable nature enables it to overcome the challenges associated with various silicon wafer types, including different crystal orientations and thicknesses. This flexibility ensures consistent and optimal drilling results, regardless of the specific parameters of the project. Manufacturers can confidently explore diverse applications in fields such as microelectronics, solar energy, and optoelectronics, knowing that the water-cooled UV laser source will adapt seamlessly to their unique requirements.

The implementation of the water-cooled UV laser source in silicon wafer drilling has also ushered in environmental benefits. Traditional drilling methods often involve the use of chemical etchants and other hazardous substances, which pose a risk to both human health and the environment. However, the water-cooled UV laser source dispenses with the need for such chemicals, promoting a safer and ecologically responsible manufacturing process. By prioritizing sustainability without compromising on performance, manufacturers can align their practices with the growing demand for environmentally-conscious solutions.

In conclusion, the integration of the water-cooled UV laser source has revolutionized the art of drilling silicon wafers. Its unprecedented power, precision, reliability, versatility, and sustainability have elevated the industry's capabilities to unprecedented levels. Manufacturers can now achieve flawless results with remarkable efficiency, propelling advancements in microelectronics and other sectors reliant on silicon wafer technology. As the field continues to evolve at a rapid pace, the water-cooled UV laser source remains at the forefront, shaping the future of semiconductor manufacturing with its potent blend of innovation and excellence.