Embarking on a Swedish Adventure: The Quest for Precision in 3D Glass Etching with RFH DPSS UV Nanosecond Laser

In the captivating realm of precision engineering and artistic ingenuity, the art of 3D glass etching stands tall as a testament to human creativity. With its ability to depict intricate designs and create captivating visual effects, this technique has piqued the interest of discerning customers seeking to elevate their craft. Such is the case of a Swedish customer delving into the realm of 3D glass etching, who embarked on an extraordinary journey fueled by the acquisition of the remarkable RFH DPSS UV Nanosecond laser.

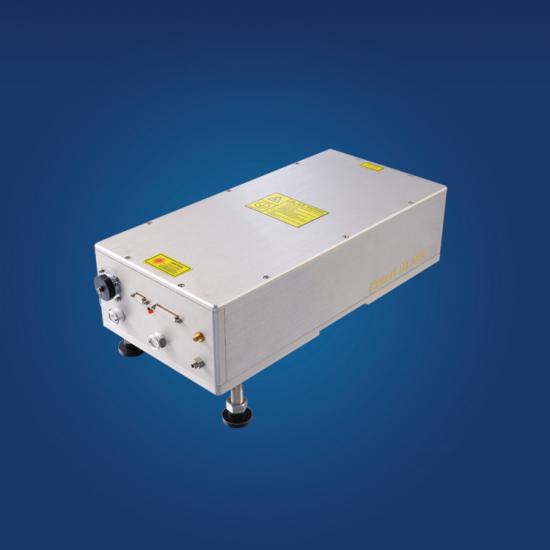

In the scenic landscapes of Sweden, where the beauty of craftsmanship thrives, the search for perfection unfolded. Eager to harness the power of laser technology, our visionary Swedish customer explored the market, searching for a tool that would breathe life into their artistic ambitions. Amidst the myriad of options, the RFH DPSS UV Nanosecond laser emerged as the pinnacle of precision, capturing their attention with its unrivaled capabilities.

This Swedish adventurer recognized the paramount importance of selecting a laser that could effortlessly bring their artistic visions to life. They understood that only a laser possessing extraordinary qualities could carve minute details and intricate patterns on glass surfaces. The RFH DPSS UV Nanosecond laser proved to be an impeccable choice, with its impressive beam quality, exceptional power stability, and impeccable pulse control offering the promise of a profound artistic transformation.

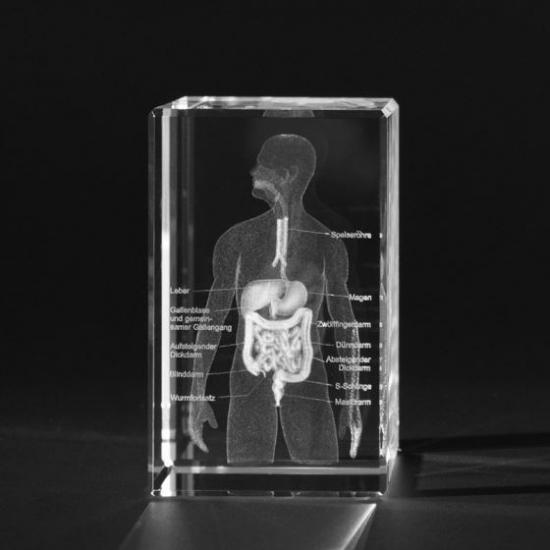

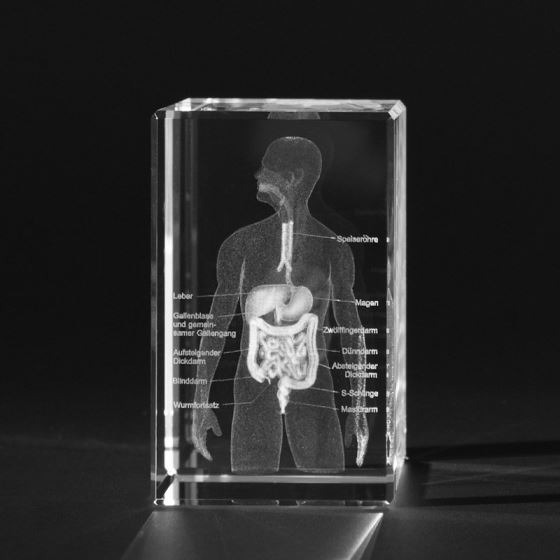

Armed with precision and fueled by a hunger for artistic expression, our Swedish customer embarked on the journey of 3D glass etching. The immersive process of creating three-dimensional designs on glass required a tool that could seamlessly blend artistic finesse with technical excellence. The RFH DPSS UV Nanosecond laser, with its cutting-edge technology and remarkable beam spot quality, became an indispensable partner in their pursuit of perfection.

As beams of ultraviolet light danced gently upon the glass surface, the RFH DPSS UV Nanosecond laser showcased its prowess in delivering astonishing precision. With each pulse, the laser effortlessly etched intricate designs, breathing life into the glass medium and evoking a sense of awe-inspiring beauty. The ability to manipulate light at such profound levels enabled our Swedish customer to push the boundaries of creativity, forging a remarkable path in the art of glass etching.

Beyond the realm of artistic mastery, the RFH DPSS UV Nanosecond laser opened new doors for our visionary Swedish customer. Its remarkable versatility allowed for the exploration of various applications, including industrial manufacturing, aerospace engineering, and even medical devices. The laser's ability to etch detailed patterns within the glass empowered countless industries to redefine their products, elevating them to new heights of excellence.

With each precise stroke of light, the RFH DPSS UV Nanosecond laser proved to be an indispensable tool. It transformed the art of 3D glass etching, empowering creative souls with a medium like no other. This Swedish customer's journey exemplified the unyielding pursuit of perfection, driven by a laser that encapsulated the very essence of precision and artistic brilliance.

In conclusion, the convergence of Swedish craftsmanship and the RFH DPSS UV Nanosecond laser unveiled a world brimming with limitless possibilities. The fusion of technical excellence and artistic finesse revolutionized the realm of 3D glass etching, transcending mere artistic expression and evolving into a realm where creativity knows no bounds. Let us celebrate the passion, vision, and boundless potential that lie at the heart of this mesmerizing collaboration, forging a path towards a future illuminated by the art of precision.