Crafting an Insightful Piece: Unleashing the Potential of High-Power Ultraviolet Lasers for Silicon Drilling

In today's technological realm, the pursuit of innovation knows no bounds. As we delve into the intricacies of cutting-edge engineering, one area that has garnered considerable attention is the application of high-power ultraviolet lasers in drilling silicon. With its remarkable precision and unmatched capabilities, this advanced technique holds tremendous potential for revolutionizing various industries.

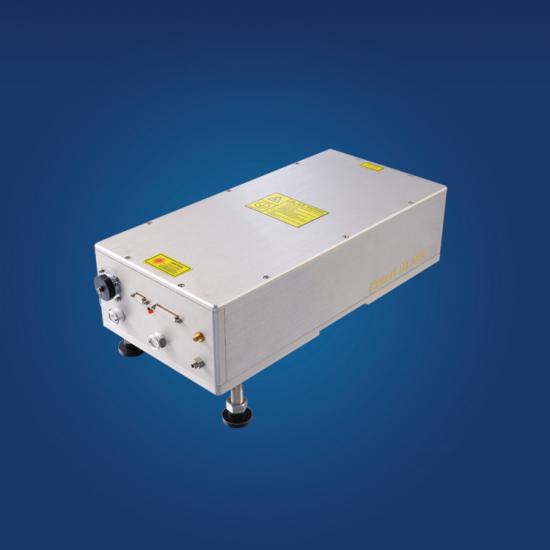

Permit me to embark on an elucidating journey, shedding light on the exceptional prowess of these cutting-edge lasers. Through their formidable energy and finely tuned wavelength, high-power ultraviolet lasers elegantly navigate the intricacies of silicon drilling, offering a quantum leap in manufacturing processes. Their unique ability to harness the power of focused light holds the key to unlocking new horizons in the realm of precision engineering.

Ultraviolet lasers, renowned for their ultrashort pulse durations and extraordinary intensity, have become the beacon of scientific breakthroughs. By leveraging these extraordinary attributes, researchers and engineers can effortlessly create microscopic channels within silicon, enabling the exploration of pioneering applications. This novel drilling technique proudly transcends conventional limitations, marking a groundbreaking departure from traditional methods.

Silicon, an elemental workhorse in the realm of semiconductors, plays an indispensable role in countless technological applications. The demand for miniaturization, coupled with escalating complexity, necessitates a technique that pushes the boundaries of precision. Enter high-power ultraviolet lasers, the vanguards of innovation, who gracefully sculpt silicon with unparalleled intricacy and finesse.

Embracing this extraordinary capability allows for the fabrication of intricate patterns and structured arrays, opening doors to advancements in photonics, microfluidics, and optical communications. The extensive range of possibilities unlocked by this method resonates powerfully with industries seeking to achieve optimal performance and unrivaled efficiency.

As we delve deeper into the practical implications, industries such as microelectronics, medical devices, and aerospace engineering stand to reap substantial benefits from harnessing the potential of high-power ultraviolet laser drilling. The ability to forge precise and complex cavities within silicon components ushers in a new era of technological capabilities, paving the way for enhanced productivity and unparalleled quality.

It is imperative to acknowledge the evolutionary significance of this groundbreaking technique. By harnessing the precision and versatility of high-power ultraviolet lasers, industries can transcend previous limitations, paving the way for paradigm-shifting innovations. The future holds boundless potential as engineers, researchers, and visionaries continue to explore the vast possibilities carved by this formidable technology.

In conclusion, the integration of high-power ultraviolet lasers as a tool for drilling silicon showcases humanity's unyielding pursuit of perfection. By encapsulating the very essence of elegance and sophistication, these lasers illuminate the path to unexplored frontiers, revolutionizing industries that thrive on the cutting edge of progress. Let us embrace this technological marvel and embark on a journey towards infinite possibilities.