RFH 3W 5W 10W UV laser cuts diamonds, smooth without bursting

Website: http://www.rfhtech.com

Whatsapp(Wechat): 18928466502

Email: export06@rfhlasertech.com

Diamonds are one of the most high-end luxury goods. They are not only bright and look very bright, but also are one of the hardest substances in the world and have a very high collection value.

But the real charm of diamonds is that after being carved by skilled craftsmen, the special beauty brought by the unique shape makes people yearn for it.

But processing and setting diamonds requires a lot of work.

No need to make a large optical path, S9 UV laser cuts diamonds without stress

When setting diamonds, it is necessary to make a "conical hole" in the base. I believe that many small partners should know that this kind of conical hole is basically made by laser.

Because the precision of traditional processing methods is not high, especially when processing jewelry such as diamond rings, the precision may not be high enough to fix the diamond well.

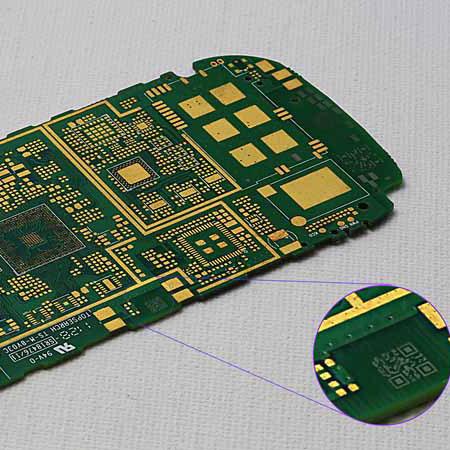

However, in addition to substrate drilling, lasers have more important applications. Have you heard of diamond marking?

On a small diamond, English letters and numbers must be typed, which is widely used in the jewelry industry.

The content of diamond marking may include a lot of information such as the size, brand or designer of the jewelry. It is not easy to print so much information on such a small diamond.

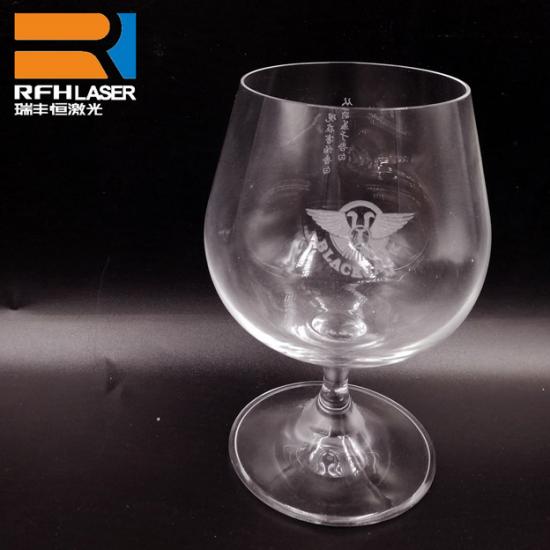

The handwriting produced by laser marking is very neat and the graphics are clear and sharp

The biggest challenge of diamond marking is not only the hard texture, but also the cost of wear and tear. After all, the cost of diamonds is much higher than that of gold and silver.

Using laser for marking and engraving, the loss of diamond body can be controlled at the level of 1/10,000 carat, and the speed is very fast compared to traditional engraving.

The RFH laser can be completed in a few seconds. If the number is large, it can be controlled by a computer to achieve automation, which greatly improves the processing efficiency. Moreover, the handwriting produced by laser marking is very neat and the graphics are clear and sharp.

To achieve such precise processing, the laser machine must be very large, right?

No need at all, RFH can use the new S9 series UV laser to complete such precise processing.

RFH S9 Series UV Lasers:

To achieve such precise diamond marking, the latest S9 series UV laser from RFH can be used. The most important thing is that the RFH S9 series UV laser is very small and does not require a large optical path, which can reduce the cost.

In addition to the compact size, due to the stable cavity structure, it can emit extremely high-quality beam quality. In terms of accuracy, the RFH S9 series UV laser can control the cutting error within ±0.02mm, and it is fully digitally controlled. Tuning can be done using a computer.

Laser processing jewelry, RFH 3-10W UV laser is reassuring

Since the RFH S9 series UV laser can be remotely controlled by a computer, the automatic diamond marking can be done after precise adjustment of parameters.

In addition to the extremely high precision, the stability of the laser is also a major challenge. A slight error will pay a very high price for processing luxury goods such as diamonds.

For a laser, the power supply will directly affect the stability of the beam. To some extent, the quality of the power supply can directly affect the beam quality of the laser.

RFH laser has the ability to independently develop power supplies, and is backed by a strong team of doctors and professors as technical support. With the support of a strong technical team, RFH laser has a unique stability and can stand the test.

It is with the strong endorsement of technical strength that RFH Laser is confident that it can perfectly cope with various challenges.

uv laser | green laser | Ultraviolet lasers | uv dpss laser | nanosecond laser | UV laser source | Solid State Lasers