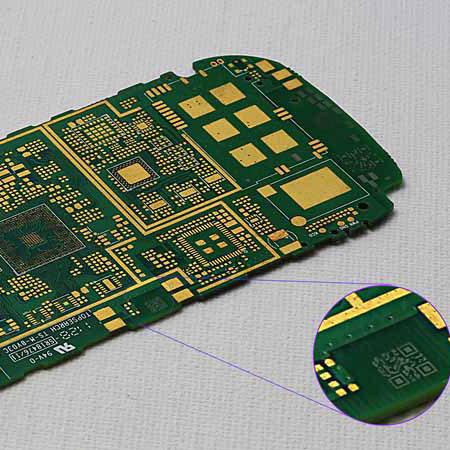

RFH 355nm UV Laser Cold Light Source Marking Plastics, No Carbonization, No Burning

Website: http://www.rfhtech.com

Whatsapp(Wechat): 18928466502

Email: export06@rfhlasertech.com

In the surface marking of plastics, there are always problems such as material being scorched, but the research and development of RFH 355nm UV laser has completely solved this problem, allowing more small and medium-sized growth enterprises whose main business is plastic marking to survive and room for development.

Plastic has a low melting point, will the surface of the plastic lamp holder be easily scorched by UV laser marking?

The cold light source marking of RFH 355nm UV laser can apply contrast marks on sensitive products. When marking the surface of plastic lamp holders, due to the small heat-affected area and almost zero thermal effect, the marking will not be affected by carbonization. , allowing material to be damaged and charred to occur.

Laser is achieving stable marking on plastic surface, also need to see RFH 3W 5W laser

In addition to the advantage of a cold light source, UV lasers also have huge advantages in terms of stability. In addition to being able to operate continuously and stably for 24 hours, the installation and operation are simple and do not require any consumables, which greatly reduces material costs. In addition, RFH cooperates with domestic first-line brand suppliers in the selection of UV laser parts to ensure the quality of parts from the source of the material procurement ecological chain, so that customers can have confidence and guarantee in the use of RFH lasers.

RFH Nanosecond UV Lasers Offer Greater Improvements in Accuracy, Operation, and Quality

RFH also provides great convenience in after-sales service, door-to-door delivery, door-to-door maintenance and remote technical guidance, etc., are gradually opened and expanded in order to serve customers to the greatest extent.

The new research and development of RFH in the past ten years has been market-oriented, with greater improvement in precision, operation and quality, and more adjustments in details, so that small and medium-sized growing enterprises have more opportunities to contact High-end laser technology has made greater progress in the domestic laser market.

uv laser | green laser | Ultraviolet lasers | uv dpss laser | nanosecond laser | UV laser source | Solid State Lasers