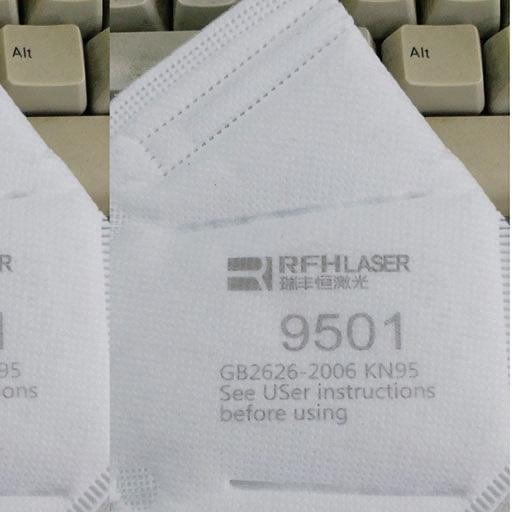

RFH 355nm UV laser marking plastic bottle caps

Date marking on bottle cap with UV laser

RFH UV laser enters the food industry, marking the date of bottle caps

Soy sauce, as an ordinary Chinese food seasoning, occupies a very important position in the kitchen. Haitian Soy Sauce, a manufacturer of soy sauce in the domestic soy sauce market, is in the hands of a company with a market value of nearly 200 billion yuan, and its valuation is even Far surpasses Kweichow Moutai, the national wine.

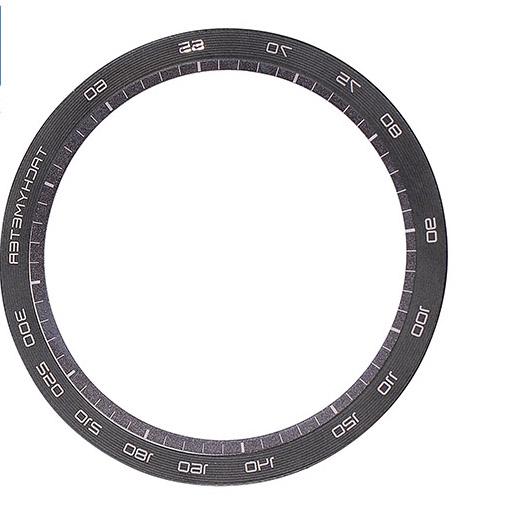

Companies that can survive the harsh environment must first ensure the high quality of their products. In order to ensure product quality and taste, every production step and all standards of Haitian Soy Sauce are extremely strict. The filling process directly affects the quality of soy sauce. The filling workshop of Haitian Soy Sauce implements a cleanliness standard of class 100,000, which is comparable to the cleanliness standards implemented by the pharmaceutical industry. In order to improve efficiency, a set of UV laser marking machine was installed on the filling production line to mark its packaging.

The RFH 355nm ultraviolet laser can obtain finer results in ultraviolet laser marking, which is favored by customers.

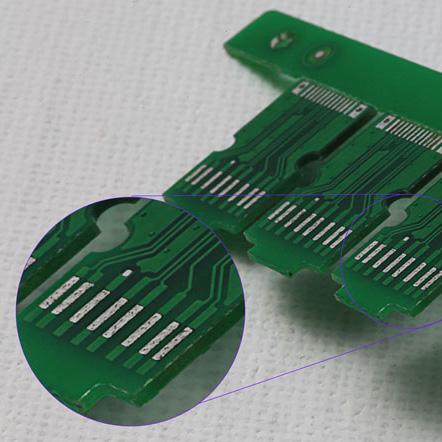

The RFH 355nm ultraviolet laser has a short pulse width (<20ns@30k), a small heat-affected area during processing, and superior beam quality (M2<1.2). It is strictly guaranteed in all frequency ranges and has perfect spot characteristics (spot ellipticity>90 %), therefore, it is so simple to complete high-precision marking tasks.

Ultraviolet marking is faster and more efficient, suitable for high-speed marking processing in food assembly lines

In just 1 second, the RFH laser can process and mark several production dates and production batch numbers, with fast speed and high stability, and the assembly line can achieve high-speed and efficient processing and production.

Ultraviolet laser is long-lived and durable, reducing production costs

The RFH laser contains an internal cavity self-purification system, so the laser has a long life and durability. In addition, it also has a unique Q-switching control technology, which can be suitable for various laser application control needs. It has multiple functions and simple operation to meet the manufacturers' multiple production application needs. In the long run, it can reduce the construction cost of a large number of new production lines for manufacturers. Really save worry and effort.

Each laser product developed and produced by RFH can maintain consistent and stable quality, constant beam quality, high-efficiency power consumption under extreme conditions of industry and scientific research, and has won all walks of life at home and abroad with excellent cost performance and high reliability. Industry users are highly recognized and have a good reputation. After 12 years of hard work, we have established an excellent brand image in the nanosecond laser industry.